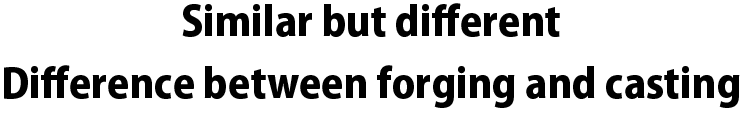

Forging is a method of metal processing. Pressure hammering metals eliminates interior voids, miniaturizes crystals, and arranges the direction of crystals to strengthen and form them into target shapes. Forging has been used to manufacture swords, arms, and hardware since long ago. The grain flow of the metal structure is connected by forming the materials into molds with under pressure, which makes the structure dense and prevents blow holes more than casting does, resulting in the manufacture of raw materials with high strength.

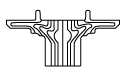

| ▶ | Forging |

|

The metal grain flows along with the form of the material  Strong against reverse bending stress Strong against reverse bending stress |

|---|---|---|---|

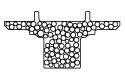

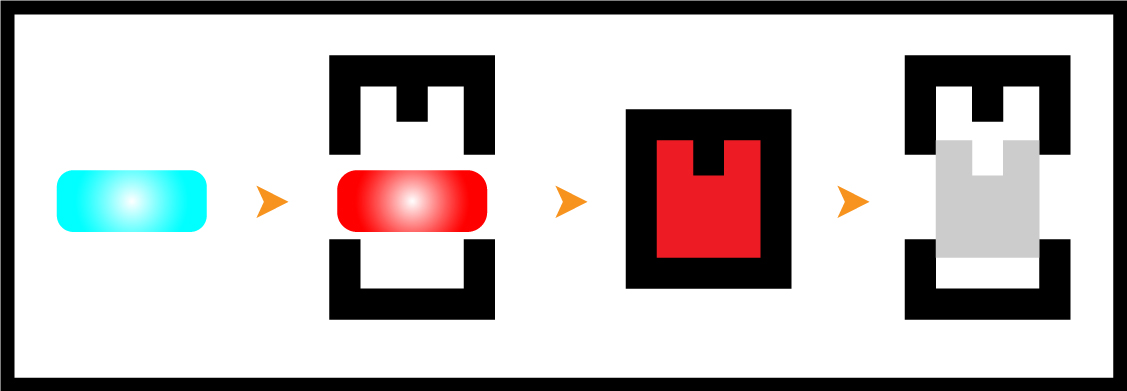

| ▶ | Casting |

|

With no metal grain flowㅤㅤㅤㅤㅤㅤㅤㅤㅤㅤㅤㅤㅤㅤㅤㅤ  Weak against reverse bending stress Weak against reverse bending stress |

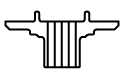

| ▶ | Machining |

|

Metal grain flow is cut in the processed section.  Weak against reverse bending stress Weak against reverse bending stress |

Forging is a manufacturing process used to shape metal by pressing it into a mold. Crimping can compensate for defects in the interior of the metal, defects such as air bubbles, and make the crystal grains of metal uniform.

Crimping with a mold makes crystal grains uniform and produces metal grain flow. These increase tensile strength and hardness.

Machining parts from steel requires longer processes and greater time to complete. Forging creates products that closely approximate the target shape due to compression with mold. This leads to reduced cutting and other after-processes, improves cutting with the application of heat, and reduces processing time.

Forging can manufacture metal into the shape closely into the target shape, and reduce the metal to be cut in after-processes. This reduces wasted materials and leads to cost reduction.

Forging with molds allows mass production.

Forging

Casting

Please use the below contact information for estimates and inquiries about our products.